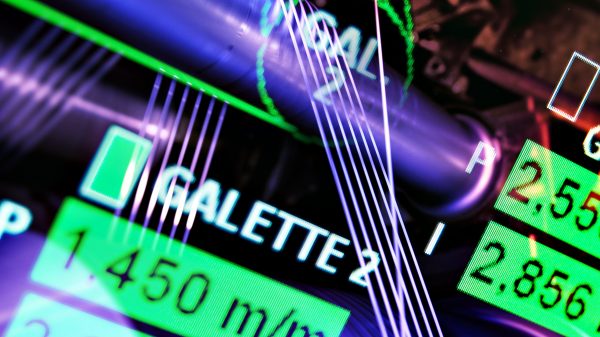

NEW – pilot multifilament spinning line

Spinning is the process whereby a material, usually a polymer, is shaped into a bundle of filaments, called a fiber. In order to shape a polymer into a fiber, the polymer must be brought into a processable liquid state. This can be done by melting the polymer (melt spinning), or by dissolving the polymer in a suitable solvent (solvent spinning). In the case of melt spinning, the liquid fiber-forming material is extruded through the small holes of a spinneret to produce a continuous filament fiber. The spun fibers solidify by cooling in contact with air after extrusion from the spinneret. In order to achieve the desired properties spun fiber is drawn and heat-treated. This can be done in a separate process, or directly in an integrated spin-draw-winding process.

Spinning is the process whereby a material, usually a polymer, is shaped into a bundle of filaments, called a fiber. In order to shape a polymer into a fiber, the polymer must be brought into a processable liquid state. This can be done by melting the polymer (melt spinning), or by dissolving the polymer in a suitable solvent (solvent spinning). In the case of melt spinning, the liquid fiber-forming material is extruded through the small holes of a spinneret to produce a continuous filament fiber. The spun fibers solidify by cooling in contact with air after extrusion from the spinneret. In order to achieve the desired properties spun fiber is drawn and heat-treated. This can be done in a separate process, or directly in an integrated spin-draw-winding process.

At SPIC Emmen, different spinning technologies are available for the R&D and production of yarns and fibers. On this page you can find some of the available machinery. Contact us for more information on the possibilities.